Application direction of Mesophase Pitch-based Carbon Fiber (2) - Mesophase Pitch-based Carbon Fiber (MPCF) Thermally/Conductive Plastic

Application direction of Mesophase Pitch-based Carbon Fiber (2) - Mesophase

Pitch-based Carbon Fiber (MPCF) Thermally/Conductive Plastic

1. About

Mesophase Pitch-based Carbon Fibers

carbonization,

and

graphitization,using

mesophase pitch, a material that is easy to graphitize, as a

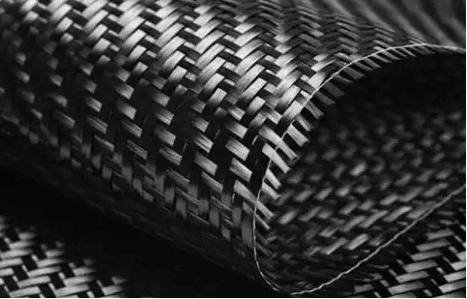

Mesophase pitch-based carbon fiber (MPCF) is processed by a series of

processes such as spinning, oxidation, carbonization, and graphitization,

using mesophase pitch, a material that is easy to graphitize, as a

precursor. The lamellar macromolecules composed of carbon elements are

aligned along the fiber axis, and the fibers are in a highly graphitized

state, showing excellent macroscopic properties such as high modulus, high

thermal conductivity, electrical conductivity, electromagnetic shielding,

damping, and low thermal expansion coefficient. The modulus can reach more

than 900GPa, and the thermal conductivity can reach 1200w/m﹒k or more.

30% specific gravity mesophase pitch-based carbon fiber chopped or ground fiber filled nylon 66 composite material can achieve the comprehensive performance level of tensile strength greater than 200MPa, flexural modulus greater than 20GPa, thermal conductivity greater than 10W/m, and volume resistivity less than 100Ω﹒cm .

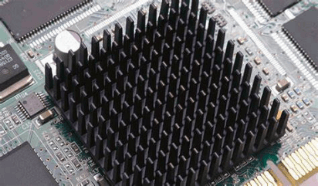

Thermally conductive plastics market application:

LED lighting radiator

Motor/Power Tool Housing

Circuit board/electronic device packaging materials

Laptop/Tablet Front and Back Covers

Conductive plastic market applications:

EMI/RFI electromagnetic shielding for mobile phones, base stations, etc.

Millimeter-wave radar electromagnetic shielding for autonomous driving systems

Hydrogen Fuel Cell Bipolar Plate

Communication base station tower suspension structure

Confidential Communication Electromagnetic Shielding

High-quality alternative to metal die-casting base station housing

Radiator

Electromagnetic shielding shell

Mesophase pitch-based carbon fiber integrates many characteristics such as light weight, high modulus, high strength, high thermal conductivity, electrical conductivity, electromagnetic shielding, low thermal expansion coefficient, and strong process designability, and will become a key material in many fields. Material core competitiveness.