Application direction of Mesophase Pitch-based Carbon Fiber (3) - Mesophase Pitch-based Carbon Fiber (MPCF) for 5G Chip Thermal Pads

Application direction of Mesophase Pitch-based Carbon Fiber (3) - Mesophase

Pitch-based Carbon Fiber (MPCF) for 5G Chip Thermal Pads

1. About

Mesophase Pitch-based Carbon Fibers

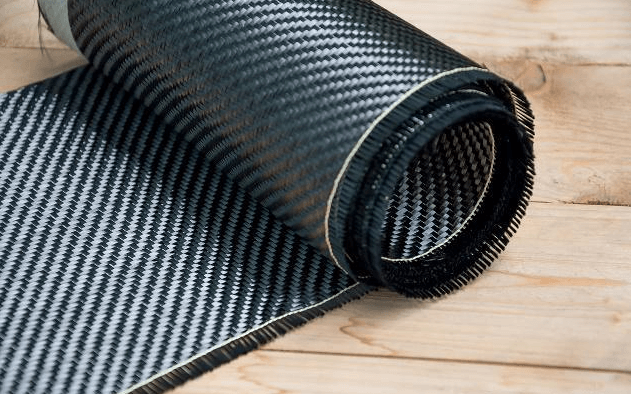

Mesophase pitch-based carbon fiber (MPCF) is processed by a series of

processes such as spinning, oxidation,

carbonization,

and

graphitization

,

using mesophase pitch, a material that is easy to graphitize, as a

precursor. The lamellar macromolecules composed of carbon elements are

aligned along the fiber axis, and the fibers are in a highly graphitized

state, showing excellent macroscopic properties such as high modulus, high

thermal conductivity, electrical conductivity, electromagnetic shielding,

damping, and low thermal expansion coefficient. The modulus can reach more

than 900GPa, and the thermal conductivity can reach 1200w/m﹒k or more.

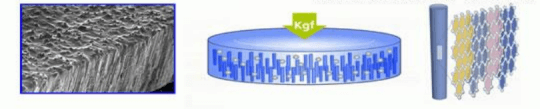

2. Mesophase pitch-based carbon fiber (MPCF) for 5G chip thermal pads

The MPCF ground fiber is compounded with the silicone rubber matrix. After the fibers are oriented and arranged in the silicone rubber under the action of flow field, electric field, magnetic field, etc., the thermal conductivity of the prepared thermal pad in the thickness direction is as high as 60W/m﹒ K or above is the preferred solution to solve the problem of heat dissipation at the 5G chip interface. A number of well-known domestic heat-dissipating materials companies have begun to adopt MPCF as a new generation of heat-dissipating technology solutions, and arrayed thermally conductive fillers to improve thermal conductivity and quality.

Radiator

Mesophase pitch-based carbon fiber integrates many characteristics such as light weight, high modulus, high strength, high thermal conductivity, electrical conductivity, electromagnetic shielding, low thermal expansion coefficient, and strong process designability, and will become a key material in many fields. Material core competitiveness.